Attrition Scubbers

We consider ourselves the global experts on Attrition Scrubbing. Why? Well, having spent over 25 years visiting plants, dealing with wear and start-up issues we undersatnd what it takes to Attrition effectively with the lowest cost per ton and lowest downtme while accieving laboratory test work result duplication.

No vortexing. No Swirl. Multiple Attritioning Zones in a single unit - maximum power utilisation.

MPTEQ Attrition Scrubbers are designed by learning from operational issues with previous designs. Some had suc a large vortex you could see the bottom of the tank, others had one impeller just to move the slurry. All had one big problem. If you look at the actual volume doing the work, it is a very small percentage of the acctual scrubber volume. The other limitation and a cause of a many failures of Attrition Scrubbers it is due to scale up issues. Test work is often done on lab scale. Often using an Attritioning attachment on a Denver D12, these have twin impellers that are spaced at 25 mm apart. The tip speed is the same as an industrial scale machine, however as the units are scaled up the distance between the impellers increases. So, in a high percentage solids enviroment the degridation of impact velocity (where the acctual work takes place) is phenomional. By the time a small attrition scrubber, of say one cubic meter, is installed. The tip speed remains the same, say 8 meters per second but the distance that particles have to travel befor impact has grown from 25 mm to over 200 mm. The impact velocity is now not 8 meters per second but 1 meter per second. How much longer will the residence time need to be to replicate the lab results? We have removed this constraint. Our travel distances are the same as the lab and we have multiple zones within a single unit.

Everything counts in order to achieve optimal Attritioning.

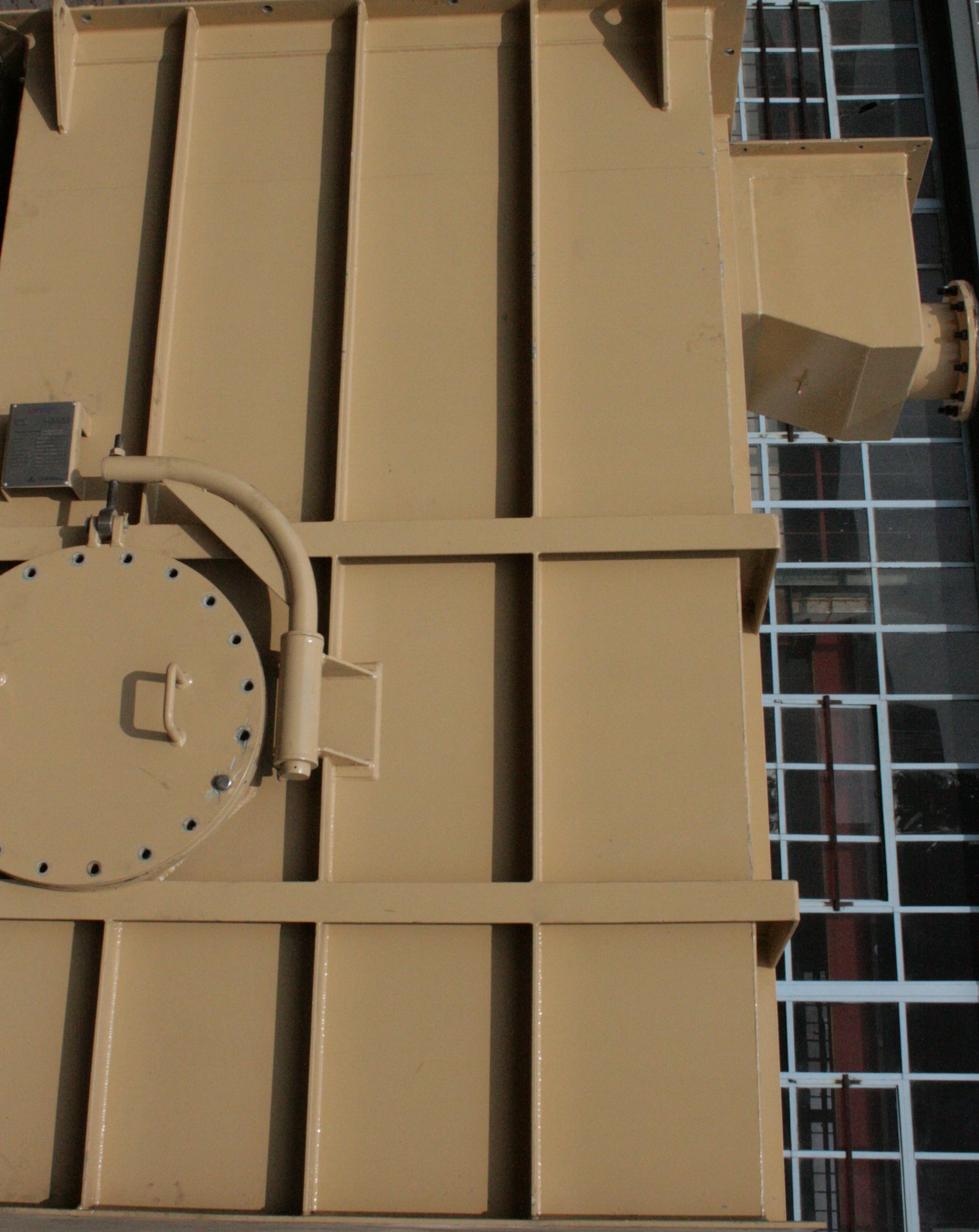

The tank must be optimally baffled. It is not adequate to rely on the tank shape to baffle the slurry and prevent plug flow, that deteriates interparticle impact. The MPTEQ tank is square (intrinsically baffled) but it also has four correctly designed and sized baffles. Off wall = D/32 Width = D/12

Automatic Drain

False economy is to install an Attrition Scrubber without an automatic drain in the event of a power failure. You can, as long as you completely was it out before restarting but... if you don't, you will damage something. A scrubber is optimally fed at over 50% solids. Within reason, the higher the better. It will lock the impeller in place after a power outage. We fit large dump valves that automatically open in the event of a power failure or plant stop. It is all collected and drained to the sump.

World Experts.

We can help you achieve your process result optimally and without headaches.